Passive Safety – Introduction

ALC/Nedal have more Passive Safe options than ever before. With bigger families of products, we can be far more flexible when designing your solutions.

The concept of passive safety was introduced to reduce the number of fatalities and serious injuries caused by road accidents. Safety is of paramount importance at ALC; it is the defining factor behind our quality-centric approach.

The impact of a vehicle on a column can cause both driver and occupants to lose conscious, if not lose their lives, in the primary accident. The uncontrolled vehicle may then career across the road and pavements resulting in secondary injuries and even fatalities to other vehicle drivers and passengers, pedestrians and cyclists.

With Passive Safety, the effects of any vehicle impact should be reduced. Passively safe columns work by absorbing energy progressively, giving the vehicle and its occupants a slower deceleration, reducing levels of injury.

ALC has a range of LE (Low-Energy) & NE (No-Energy) passively safe columns. ALC also supplies HE (High-Energy) passive columns, but we believe that most passive installations in the UK should be NE or LE.

This is because the new BS EN 12767:2019 standard reinforces safeguarding of vehicle occupants as the primary objective.

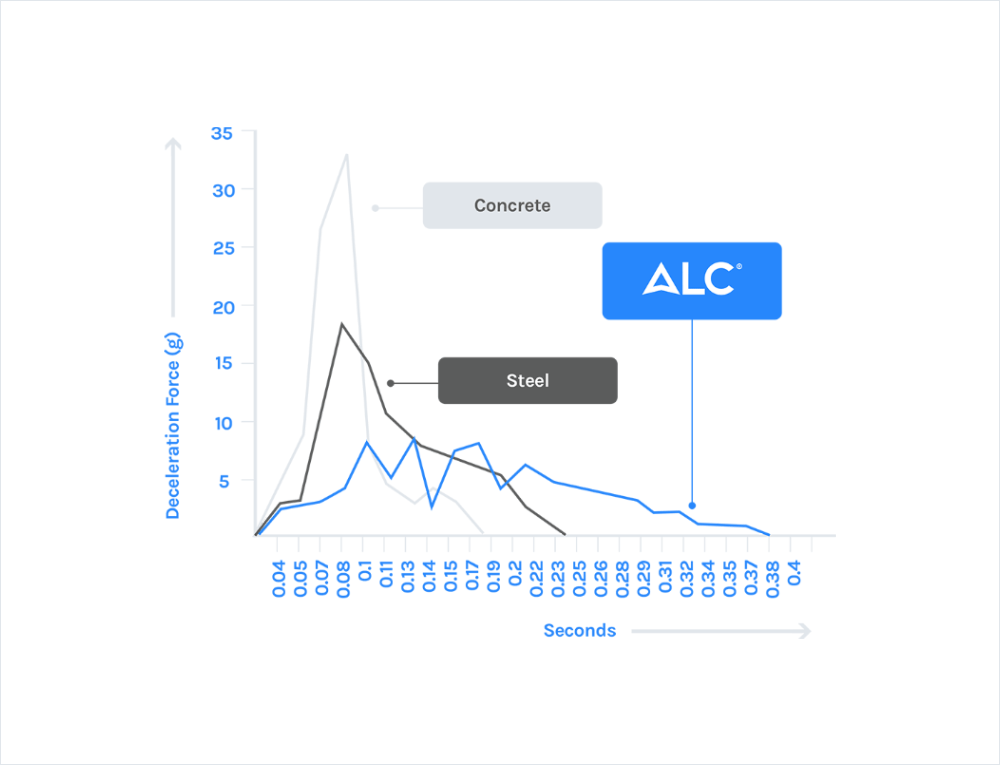

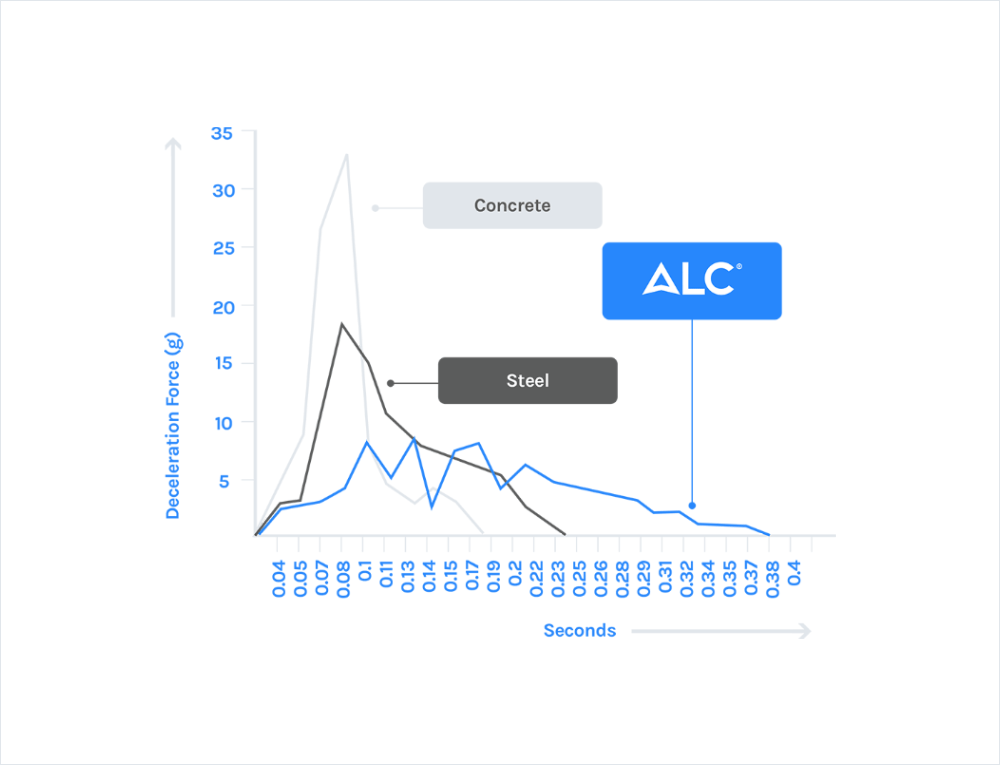

The above graph depicts different G-forces experienced by vehicle occupants in a 23mph collision with structures of 3 different materials: Aluminium, Steel and Concrete. Data from ‘D. M. Paylor MIEE C.eng FILE FRSA, ‘Aluminium Lighting Columns – The Way Forward to the 21st Century’.

The Material Comparison graph illustrates the very different behaviours of steel, concrete and aluminium after a collision. Both steel and concrete show very big spikes in g-force immediately after impact. This very high g-force will have a profound effect on the driver and occupants. In contrast aluminium does not have a high spike in g-force and the graph shows a smoother, flatter reaction. This means there is a much better experience for the driver and occupants.

Download the Material Comparison graph here.

The energy absorption ability of a column influences their passive safety rating considerably, and depends on various factors such as structural form, but in regards to the material used:

Steel: – Absorbs large amounts of energy due to its unforgiving material properties; the vehicle undergoes rapid deceleration generating high g-force for both driver and occupants. It is this g-force that induces loss of consciousness and can kill. – The impact will also severely damage the vehicle, possibly making control after the primary accident difficult.

Aluminium: – Has greater elasticity and therefore absorbs smaller amounts of energy. This means that the vehicle undergoes a much slower deceleration with a much-reduced g-force. – The damage to the vehicle is likely to be less serious, making it easier to control to prevent secondary accidents.

How the column reacts during and immediately following impact is also important. In our experience ALC passively safe columns are designed to yield at the base, allowing the vehicle to pass over the collapsed column. Below are some images of a road traffic collision column involving an ALC column.

It has performed exactly as it should: the column folded over. Notice the absence of a vehicle in the picture; this was the third time a column had been hit in the same location and thankfully on each occasion the driver was able to drive the vehicle away from the scene.

The generalisations about column behaviour after impact in the UK National Annexe to BS EN 12767:2019 are not part of our experience.

In our experience, our root mounted passive columns do not detach at the base.

01639 852 502

01639 852 502