At ALC, we base our approach to the design and manufacture of aluminium lighting columns on decades of investment in facilities and technical expertise.

By investing in these, we give our talented teams the tools they need to deliver results, and give our clients a breadth of options.

We aim to provide our clients with plentiful and convenient options, not force a compromise.

In-House Design & Technical

It’s this commitment to continuous improvement that allows us to evolve, adapt, and remain at the forefront of our industry. The clearest impact can be seen in design.

Additionally, our in-house Design & Technical Team make sure clients have full access to complementary technical and design support.

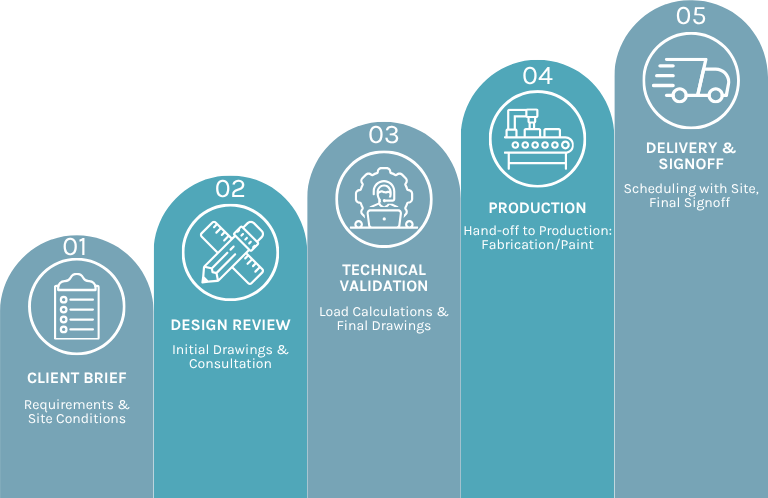

Nevertheless, our facilities and processes define our scope.

Moreover, we continuously assess our facilities and processes. In doing so, we identify opportunities for improvement promptly, rectify them, and broaden our capabilities.

It’s this commitment to continuous improvement that allows ALC to retain our trusted position in the industry.

This means we deliver solutions built on the latest technology and methodology. As a result, we can competently and consistently solve complex, persisting issues.

However, this also applies in a more general sense.

We tackle complex cases with care and bring the same innovative approach to everyday operations.

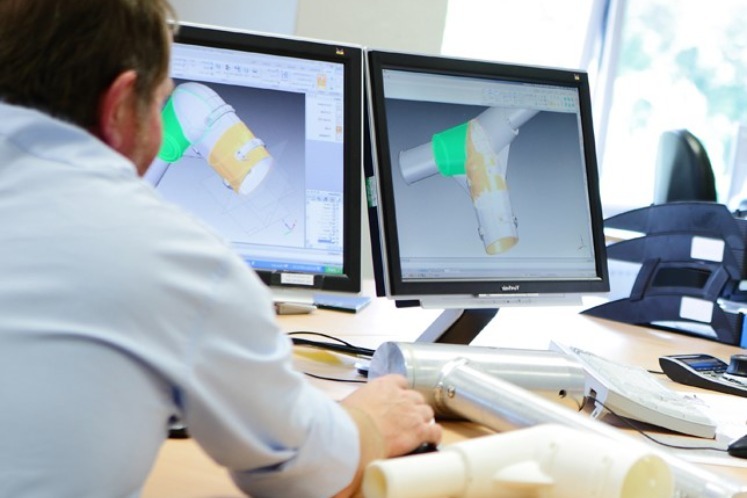

We rigorously assess and review every project. Using tools such as Solidworks and Calcuround, our solutions account for specific site conditions and attachments, ensuring safety without compromise.

This means we always select the most suitable solution for each application without exception. This gives our clients peace of mind going into every project they tackle.

Aluminium Lighting Columns – Manufacturing & Fabrication

Manufacturing and fabrication remain the cornerstones of our business. We aim to provide flexibility, tailoring solutions to address every requirement.

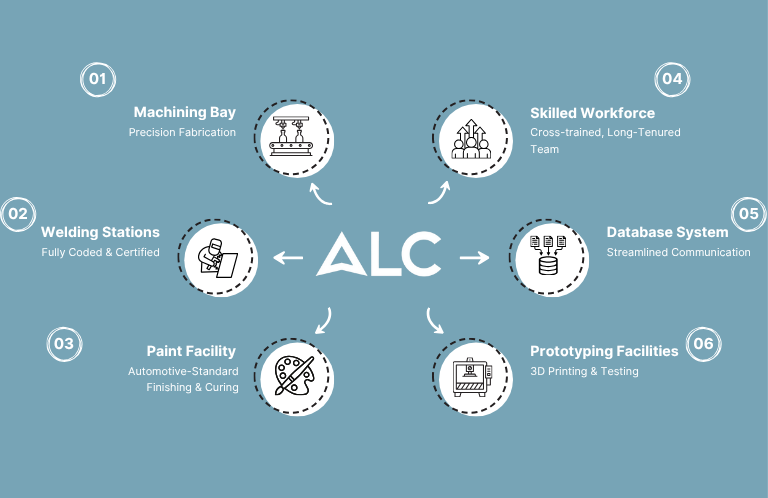

We achieve this through a range of quality facilities, from a suite of design and prototyping solutions, to a dedicated machining bay and fully coded welders.

Our facilities, refined across three decades in the industry, have empowered our in-house Design Team to innovate. This gives our Sales Team confidence to say yes.

Likewise, we prioritise the upskilling, cross-training, and retention of our production staff. Clients trust ALC to meet every challenge with consistent skill and reliability.

Retaining experienced staff means preserving expertise.

It also means the close inter-departmental relationships that exist are preserved, which keeps both our internal and external communications seamless.

In turn, all departments consistently look for opportunities to improve both process and customer experience.

This responsibility is shared across the business – recent examples include:

- Database & Communications – Comprehensive database system under constant review. Makes sure swift, accurate communication exists between office & production teams.

- Prototyping Facilities – 3D printing technology installed for rapid iteration of new products: from component interference to final demonstration to clients.

- Product Manuals & Animation – Ever-improving quality, quantity and accessibility of resources for our clients to extract maximum value from our deployed solutions.

We design every improvement to shorten lead times, enhance quality, and upgrade working conditions for our staff.

Aluminium Lighting Columns – Supply Chain

Our facilities, processes and capabilities are of utmost importance. However, this must also extend to our supply chain.

That’s why we choose partners who share our commitment to precision across their operations.

This alignment is essential. It extends beyond suppliers of components to providers of maintenance, training and logistics services.

As a result, our operations and products consistently meet the highest standards from start to finish. This gives clients confidence in what we can deliver.

After all, these suppliers are integral to our success.

Through close collaboration, we maintain strong communication channels across every level of the chain, giving our clients clear benefits.

Key Suppliers – Nedal Aluminium

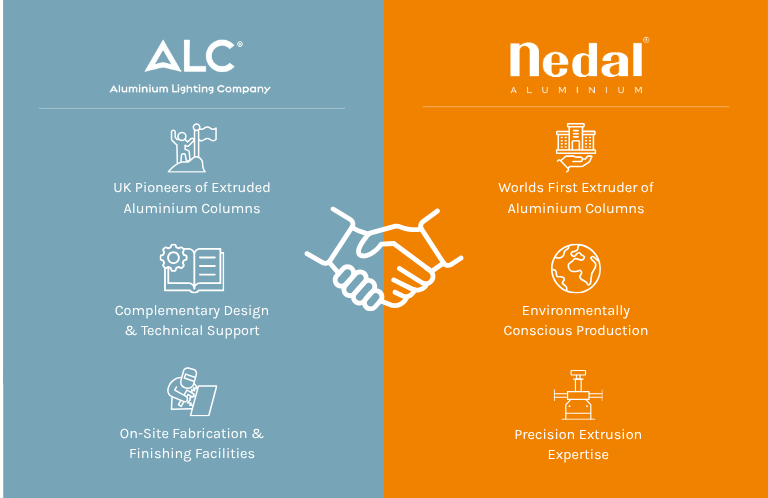

For example, few partnerships illustrate this better than our long-standing relationship with Nedal Aluminium B.V.

Founded in 1938, Nedal Aluminium B.V. is the world’s longest-established manufacturer of extruded aluminium lighting columns.

We have been their exclusive UK partner for over 30 years. In this time, our companies have developed a synergy which has proven invaluable.

Crucially, as participants in the European IRIS Smart Cities Project involving cities such as Nice and Nedal’s home of Utrecht, they apply the same tenets of innovation we value.

For example, Nedal have worked with engineers of The Municipality of Utrecht and Citytec to deliver a smart lighting column solution for a pedestrian crossing.

The solution included solar panels, noise and air quality meters. Also, vehicle speed sensors and pedestrian motion detection were added to light the crossing on demand.

As a result, lighting columns are increasingly seen as valuable assets for Smart Cities. Nedal and ALC identified this trend early, consistently engaging in related initiatives.

As Edwin Meerbeek of Nedal comments in the below video:

“We will eventually notice that a light pole will not stay an ordinary light pole”

As their UK partner, we benefit from this culture of innovation. This translates into solutions that set the benchmark for performance.

With this emphasis on sustainability, innovation & service, our values align. We rely on this synergy to deliver the quality aluminium lighting columns & service ALC is known for.

Problem Solving & Innovation

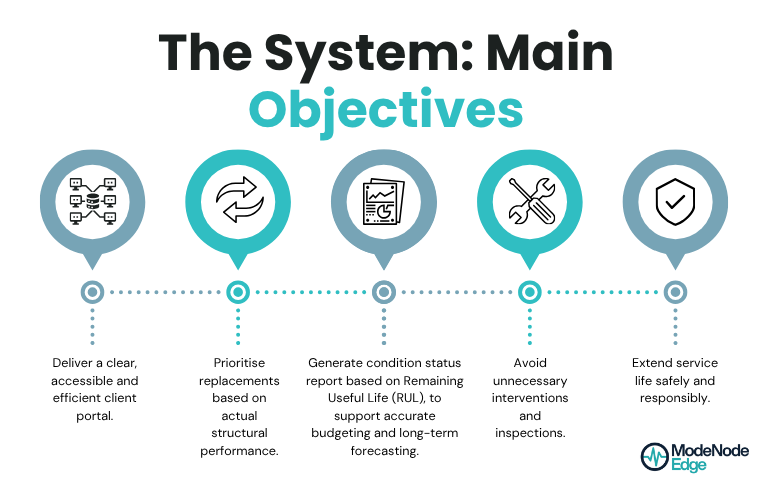

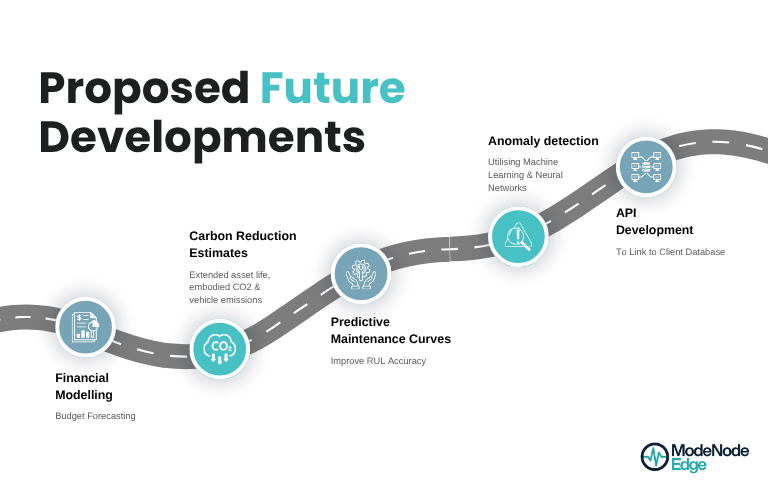

After a decade of development, a pilot deployment of ModeNode Edge, ALC’s Structural Condition Monitoring System (SCMS), is underway in Utrecht.

Considering Utrecht’s enthusiasm for new tech and our close ties to both Nedal and the municipality, this pilot promises to be instrumental in the full realisation of the product.

ModeNode Edge creates digital twins of each structure, enabling remote monitoring. Via a secure portal clients receive updates, including remaining useful life (RUL) estimations.

Early insight helps identify problems, triggers instant alerts, and guides quick action – reducing costs and waste while ensuring repairs or replacements are justified.

AI and machine learning power ModeNode Edge. It continuously learns from data to enhance its capability and accuracy.

In conclusion, our priority is to deliver results both in our innovation and our everyday operations.

As a result, our products deliver better reliability, lower lifetime costs, simpler maintenance and safer operation.

In Summary

What ties all of this together is quality. Quality of facilities, processes, culture, talent, communication, leadership and strategy.

These aspects, in plentiful supply across the company and our supply chain, create an environment in which creativity and competence can thrive, and innovation is championed.

As a result, the client becomes the priority. Quality product is the baseline, innovation is the imperative – but not for its own sake.

Instead, we see innovation as the mechanism through which we achieve our unbeatable quality and service.

01639 852 502

01639 852 502